25 JANUARY 2017

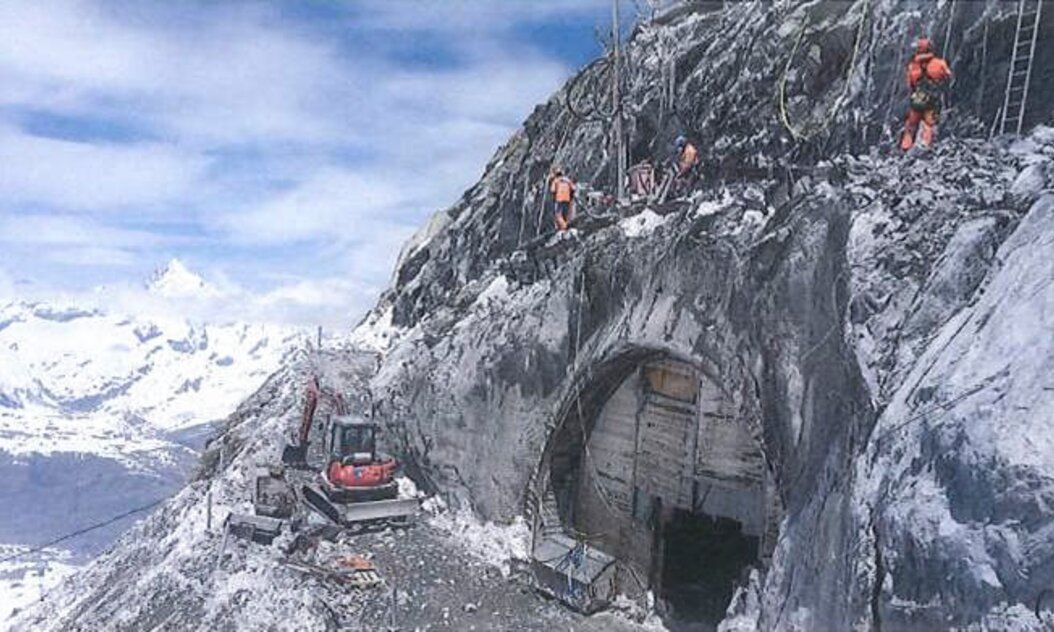

Gasser Felstechnik AG has been working in and on mountains since 1922. The company’s areas of expertise include blasting work as well as rock stabilization. Having completed the work on the transport cableway from Lake Cime Bianche to Klein Matterhorn, Gasser Felstechnik AG was contracted to carry out the rock stabilization and excavation work for the new 3S cableway’s mountain station.

An exposed and challenging construction site like this on the Klein Matterhorn is no everyday commission even for a company with Gasser’s long tradition. Only the most experienced staff are brought in to work on the Klein Matterhorn site: members of the rock stabilization department who specialize in dealing with natural hazards, working in mountainous terrain, carrying out rockfall prevention and blasting work. Gasser Felstechnik is working tirelessly to complete the preparatory work ready for the construction company to move in. The following essential installations were put in place during the first phase of the project, from 2015 to 2016:

Anchorages for the transport cableway, the signal cable and the foundations for the crane

The foundations for the transport cableway have to absorb enormous forces once the hauling cable is in place. To secure the foundations, ten 10-metre anchoring rods were drilled into the base rock facing the direction that the loads will be drawn, and the protruding sections then concreted into the footings. For each anchor, a hole with a 15 cm bore is drilled into the rock using a lightweight drilling machine. Ribbed steel rods with a diameter of four centimetres are then inserted and the holes back-filled with special permafrost-resistant cement. The most important and difficult part of the procedure is getting the cement mix exactly right, because if it doesn’t set properly the anchor will not hold. There is no room for error here, so all the anchors are tested by an outside company to ensure that they are correctly secured once the cement has set.

Anchoring the signal cable is carried out along the same lines as the foundations for the materials cableway, but fewer anchors are required as the loads involved are considerably smaller – there are only six anchors, and each is six metres in length.

The foundations for the crane were reinforced in the same way as those of the materials cableway, due to enormous tensile and compressive loads to which the crane is subjected. Sixteen 8-metre anchors were drilled into a base area of 3.5 by 3.5 metres.

A total of five tonnes of steel were used to anchor the foundations for the materials cableway, the signal cable and the crane.

Rockfall and snow protection netting

Before installing the rows of netting, the entire rockface had to be cleared of loose material in order to ensure the safety of the construction workers. Armed with picks and crow bars, workers abseiled down the rockface from the ridge above and removed all the loose surface rocks from an area of 3000 m2. Then the highest-risk sections, covering a total area of 1500 m2, were clad in wire mesh pinned into the rock surface. Across a grid marked out in

3-metre squares, two holes were bored a metre deep into the rock in each square to accommodate the steel rods, which were then glued in place. Hexagonal mesh netting was laid onto the surface of the rock and fixed to the steel pins with metal plates. Ten tonnes of steel went into the construction of the mesh. After this, four rockfall and snow protection nets were fitted above the mountain station at a height of five metres, extending for a length of 200 metres. These will protect the construction workers while the station is being built. On completion of the building work they will provide permanent protection for the new station.

In 2017 further protective netting is due to be put in place between the new and old stations to guard the gondolas from any falling rocks. This netting will be made from four tonnes of steel and secure a surface area of 1000 m2.

Blasting work

With measures in place to protect against rockfall it was then possible to begin blasting work to excavate the site of the new station. The biggest challenge here was how to get the drilling machines on site as there was no proper surface on which to transport them. A decision was made to build two temporary roads to the highest point of the construction area so that the heavy drills could be used to start the excavation work from the top. The limited amount of space and the difficult geological conditions presented Gasser Felstechnik with a number of challenges. At the end of the day, around one-third of the excavation work was done using manual drills and two-thirds with a heavy-duty drilling machine. Vertical holes were bored to a depth of two to three metres and filled with explosives. This blasting technique was used on 30 holes a day. Five tonnes of explosives were used to excavate a total of 10,000 m3 of rock.

The greatest challenges

The extreme winter weather conditions are very difficult to cope with. Workers have to battle in temperatures as low as minus 30 degrees Celsius and wind speeds of over 60 km/h, so they are all equipped with expedition gear. These temperatures are not only tough on the workers, they also take their toll on the materials. During the first phase between 2015 and 2016 there were no storage sites and all the equipment had to be kept outside, exposed to the extreme weather. For the equipment to work properly at these temperatures and altitudes it first has to be adapted in the workshop and special additives have to be incorporated into the compressed air flow during operation. At first the only available lifting device was the helicopter, the use of which also depends on favourable weather conditions. Since the summer of 2016, a 52-metre crane has been on site for use in good weather. It is being used as a base from which to drill most of the bore holes and trenches. All the equipment is packed in containers and buried in the snow on the construction site so that it can be readied for use quickly even when poor weather restricts access to the site.

The construction of the 3S cableway has presented us as lift operators and all of our partner firms with massive, but not insurmountable, hurdles. We are extremely pleased to be able to rely on the expertise of our partners.

Key volumes 2015–2017

Steel: 60 tonnes

Excavated material: 10,000 m3

Explosives: 5 tonnes

Mesh netting: 3000 m3

Rockfall protection netting: 200 m

Permanent anchorages checked: 500 m